Plastics

7 minute read

Bio-based? Recyclable? Biodegradable? Your guide to sustainable plastics

With sustainability high on everyone’s agenda and technology advancing fast, the world of plastics is changing. Here’s what you need to know about modern plastic materials – and the sometimes confusing terminology, explained by science journalist Sandrine Ceurstemont.

Plastic waste has become a global concern. Nearly four hundred million tons of it are produced globally every year, while 79 percent of all plastic waste ever produced have ended up in landfills or as litter in natural environments.

But what about new, more sustainable plastics – will they help us tackle the plastic waste challenge? What do the terms bio-based, biodegradable or recyclable plastics actually mean, and how can they help us achieve ambitious sustainability targets and cut down the need for crude oil in plastics production?

We will take you through some of the most common terms associated with sustainable plastics and uncover the facts behind each one.

Bioplastics – plastics that are bio-based or biodegradable or both

Bioplastics is a term that is used to refer to plastics that are bio-based, biodegradable, or fit both criteria.

In contrast to traditional plastics made from fossil-based feedstock, bio-based plastics are fully or partly made from renewable feedstock derived from biomass. Commonly used raw materials to produce these renewable feedstock for plastic production include corn stalks, sugarcane stems and cellulose, and increasingly also various oils and fats from renewable sources. The terms ‘bioplastics’ and ‘bio-based plastics’ are often used interchangeably by laypeople but they don't actually mean the same thing.

Biodegradable plastics are plastics with innovative molecular structures that can be decomposed by bacteria at the end of their life under certain environmental conditions. Not all bio-based plastics are biodegradable while some plastics made from fossil fuels actually are.

Bio-based – plastics that contain components produced from biomass

Plastics that are bio-based are partially or completely made from material that has been produced from biomass instead of fossil-based raw materials. Some are biodegradable but others are not.

In 2018, 2.61 million tons of bio-based plastics were produced worldwide, according to the Institute for Bioplastics and Biocomposites (IfBB). But that is still just less than 1% of the global plastic market. As demand for plastic continues to grow, so is the demand for more sustainable plastics solutions. Conventional fossil-based plastic can be replaced with drop-in plastic – a bio-based equivalent. This can help reduce the carbon footprint of the end product while the other characteristics of the product – its durability or recyclability – for example, remain the same.

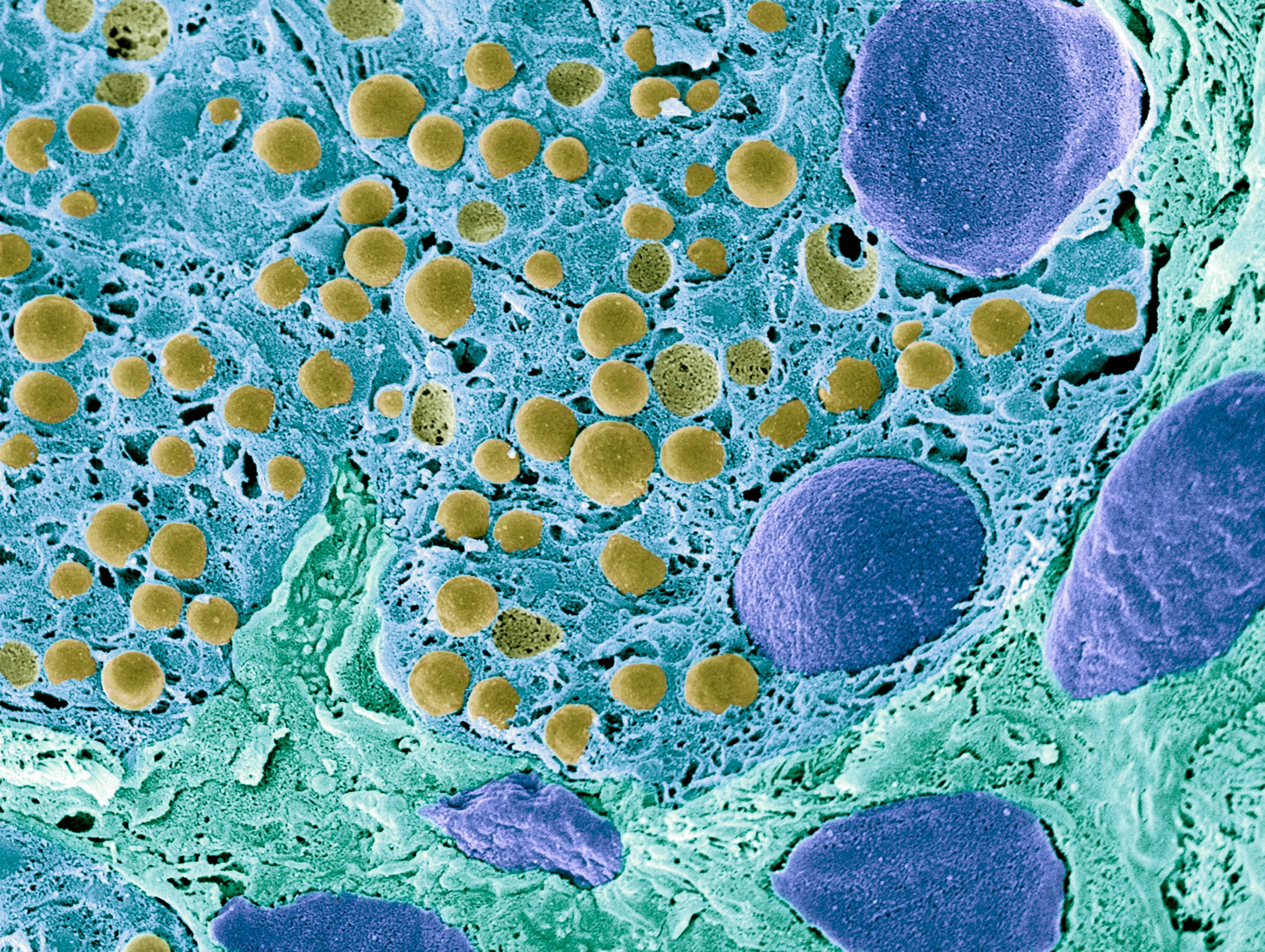

Polyhydroxyalkanoate or PHA, is a common type of biodegradable bio-based plastic, currently used to make packaging and bottles, for example. It is produced by industrial fermentation when certain bacteria are fed sugar or fat from feedstocks such as beets, sugar cane, corn or vegetable oil. But unwanted byproducts, such as waste cooking oil or molasses that remain after sugar manufacturing, could be used as alternative feedstock, freeing up food crops for other uses.

"As demand for plastic continues to grow, wider range of bio-based plastics have entered the market and should increasingly be used as an alternative."

Some bio-based plastics, such as, drop-in plastics have identical chemical structures and properties to conventional plastics. These plastics are not biodegradable, and they are often used in applications in which durability is a desired feature.

Bio-based PET, which is partly made from the organic compound ethylene glycol found in plants, is used in many products such as bottles, car interiors and electronics. As customer demand for more sustainable plastics increases, the market for this plastic is expected to grow by 10.8% from 2018 to 2024, compounded annually.

Bio-based polypropylene (PP) is another drop-in plastic that can be used to make products such as chairs, containers and carpets. In late 2018, commercial scale production of bio-based PP took place for the first time, producing it from waste and residue oils, such as used cooking oil.

Biodegradable – plastic that decomposes under specific conditions

If a plastic is biodegradable, it means that it can undergo decomposition under certain environmental conditions and when in contact with specific bacteria or microbes – turning it into water, biomass and carbon dioxide, or methane, depending on aerobic or anaerobic conditions. Biodegradation is not an indication of bio-based content; instead, it is linked to the molecular structure of a plastic. Although most biodegradable plastics are bio-based, some biodegradable plastics are made from fossil oil based feedstock.

The term biodegradable is ambiguous since it doesn't specifiy a timescale or environment for decomposition. Most plastics, even non-biodegradable ones, will degrade if they are given enough time, for example hundreds of years. They will break down into smaller pieces that can be invisible to the human eye, but remain present as microplastics in the environment around us. In contrast, most biodegradable plastics will biodegrade into CO2, water and biomass if they are given enough time under specific environmental conditions. It is advised that detailed information about how long a plastic takes to biodegrade, the level of biodegradation and required conditions should be provided to better evaluate its environmental credentials. Compostable plastic, a type of biodegradable plastic, is easier to assess since it must meet defined standards to merit a label.

Compostable – a type of biodegradable plastic

Compostable plastics are a subset of biodegradable plastics. Under composting conditions, it is broken down by microbes into CO2, water and biomass.

For plastic to be certified as compostable, it must meet certain standards. In Europe, that means that in a timeframe of 12 weeks, 90% of the plastic must decompose into fragments less than 2mm in size in controlled conditions. It must contain low levels of heavy metals so that it doesn’t harm soil.

Compostable plastics need to be sent to an industrial facility where heat and humid conditions are applied in order to ensure degradation. PBAT, for example, is a fossil feedstock based polymer that is used to make organic waste bags, disposable cups and packaging film and is biodegradable in composting plants.

Plastic that breaks down in open environments such as in household compost heaps is typically hard to make. PHAs, for example, fit the bill but are not widely used since they are expensive to produce and the process is slow and hard to scale up. However chemists have been working on improving this, for example by using a novel chemical catalyst – a substance that helps increase the rate of a chemical reaction.

Recyclable – turning used plastic into new products by mechanical or chemical means

If plastic is recyclable, it means that it can be reprocessed at an industrial plant and turned into other useful products. Several types of conventional plastics can be recycled mechanically – the most common type of recycling. But the first global analysis of all plastic waste ever generated found that only 9% of plastic has been recycled since the material started being produced about six decades ago.

Mechanical recycling involves shredding and melting plastic waste and turning it into pellets. These pellets are then used as a raw material to make new products. Plastic quality deteriorates during the process; therefore a piece of plastic can only be mechanically recycled a limited number of times before it is no longer suitable as a raw material. New plastic, or ‘virgin plastic’, is therefore often mixed with recycled plastic before it is turned into a new product to help reach the desired level of quality. Even then, mechanically recycled plastics are not fit for all purposes.

"Chemically recycled plastic can replace virgin fossil oil based raw material in the production of new plastics."

Chemical recycling, whereby plastics are transformed back into building blocks and then processed into virgin-quality raw material for new plastics and chemicals, is a newer family of processes that is now gaining momentum. It typically involves catalysts and/or very high temperature to break down plastic and can be applied to a wider range of plastic waste compared to mechanical recycling. For example, plastic films containing multiple layers or certain contaminants cannot usually be mechanically recycled but can be chemically recycled.

The raw materials created from plastic waste in the chemical recycling process can be used to replace virgin crude oil based raw materials in the production of new, high-quality plastics.

One of the main benefits of chemical recycling is that it is an upgrading process in which a plastic’s quality doesn’t degrade once processed unlike during most types of mechanical recycling. The resulting plastic can be used to make a wide range of products including food containers and items for medical and healthcare uses where there are strict product safety requirements.

Credits: Sandrine Ceurstemont, a science and tech journalist whose work has appeared in The Guardian, National Geographic, BBC Earth and Scientific American.