Renewable solutions

6 minute read

Singapore refinery expansion: a milestone to cut our dependence on fossil energy

The recent expansion of Neste’s Singapore refinery results in a significant increase in not only the capacity to produce renewable products, but also to develop the use of raw materials from new streams. What does this mean in our global challenge to combat climate change?

The urgency to find, apply and scale up solutions to reduce greenhouse gas emissions has been an increasingly hot topic since the Paris Agreement on climate change called for emissions to be cut by 43% by 2030, if we are to limit global warming to 1.5°C. The global agreement at the COP28 in December 2023 to transition away from fossil fuels has highlighted the importance of cutting our dependency on fossil fuels if we are to achieve that goal - and the solutions to do this include replacing fossil products with renewable alternatives.

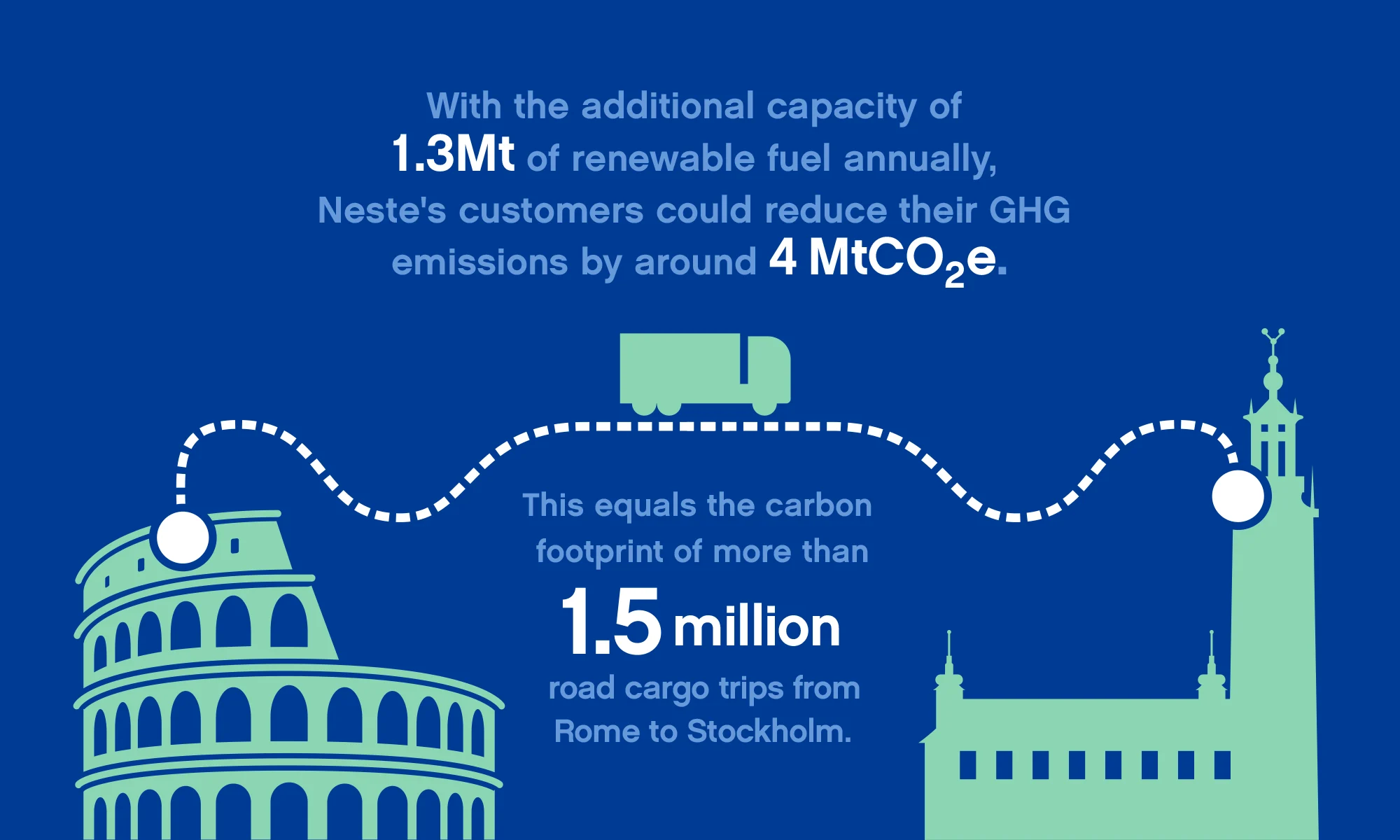

Neste, a global leader in the production of sustainable aviation fuel (SAF), renewable diesel and renewable feedstock solutions for the polymers and chemicals industry, is showing the way with the expansion of its Singapore refinery. The expansion doubles the site’s production capacity from 1.3 to 2.6 million tons per year. This will result in a significant increase in the availability of sustainable aviation fuel (SAF), renewable diesel and renewable raw materials for the polymers and chemicals industry.

Distance : 2824 km, Source : HDV Group 5 emission factor and average payload from Prussi, M., Yugo, M., De Prada, L., Padella, M., Edwards. JEC Well-To-Wheels report v5. EUR 30284 EN.

What does this mean in practice? A boost to decarbonize cities, fewer transport emissions and more sustainable plastics among others – making all-important inroads into the global target of cutting our emissions and accelerating our transition towards a more sustainable future.

Aviation and transport: cutting the fossil fuel umbilical cord

The aviation industry is responsible for 2-3% of global CO2 emissions – a figure that is set to increase with the appetite for flights picking up pace again since dropping due to the pandemic and due to other sectors decarbonizing comparatively faster. The industry has however set a goal to achieve net-zero carbon emissions by 2050. To achieve this, a combination of solutions will be needed, such as new aviation technologies and increasing the use of SAF. New low or zero-emission technologies, such as electric flying, are still in early stages of development, but SAF is already available and can be used now as a drop-in solution in existing aircraft and fuel infrastructure.

The expansion of the Singapore refinery increases Neste’s global SAF production capability to 1 million tons per annum – a significant step forward to increasingly enable consumers and businesses to choose to fly more sustainably.

Source : ICAO, economy class

Neste is also expanding its global network of airports where it has the capability to supply SAF directly into aircraft. For example, at Singapore Changi Airport, a leading aviation hub in the Asia-Pacific region, an integrated SAF supply chain will enable airlines to refuel with SAF and reduce their emissions on their routes in the Asia-Pacific region and beyond.

“We're currently seeing a significant demand growth for sustainable aviation fuel, and our supply capabilities at Changi Airport will really help the market to access our solutions for decarbonizing the aviation industry,” says Carl Nyberg, Executive Vice President, Renewable Supply Chain and Sustainability at Neste.

Singapore government’s latest decision detailed in the Sustainable Air Hub Blueprint, to adopt a new national SAF target for flights departing the country will further support such initiatives.

Meanwhile, long-haul ground transportation will benefit from the increased availability of renewable diesel. “Long-haul heavy duty transport, as well as heavy duty off-road machinery in mining and construction, will still need liquid fuels for a long time,” Nyberg points out. “Electrification is unlikely to solve the need to cut emissions there very quickly.”

Decarbonizing big cities

Most of the world’s population lives in cities, and growing urban areas are responsible for the majority of global carbon emissions.

“Cities play an important role in showing the direction for how we are decarbonizing our society,” says Nyberg. “Cities typically take a much more progressive stance on these things than nations.”

There are many aspects to decarbonizing urban areas, such as converting existing buildings to be more energy efficient, creating more climate-friendly new buildings, educating people on environmental issues and introducing measures to limit the carbon emissions of local traffic and industry.

“Many utility vehicles operating in cities are typically powered by diesel,” notes Nyberg. “And typically the life cycles of these vehicles are rather long. So for quite some years you will still have a large diesel fleet that needs to be decarbonized in some way."

That includes local goods transport, vehicles used in construction as well as local transport such as city buses, all of which can lower their emissions with renewable fuels today, without major investments. Nyberg explains: “You don't have to make any changes to the vehicle fleet or the infrastructure to use renewable fuels, such as Neste’s renewable diesel.”

The expanded Singapore refinery will also give a boost to the circular bioeconomy. It enables an increased production of renewable feedstocks for the manufacturing of more sustainable polymers and chemicals, such as plastics that can be used in products ranging from pacifiers to coffee cups and car parts.

“The plastics industry is in a big need of renewable and circular solutions. We’re seeing an increasing interest in our solution that provides alternatives to produce materials such as plastics or chemicals from renewable sources. We have over the past years been increasingly moving into that space,” says Nyberg.

Development of new waste and residues streams

The increased production capacity and enhanced pretreatment capabilities at the Singapore refinery mean greater opportunities to work with a wider range of raw materials. Broadening the pool of raw materials that can successfully, safely and sustainably be used to produce renewable products, is an essential part of the scaling up process.

“It's really about expanding the access to renewable raw materials that can be used in producing renewable solutions,” says Nyberg. “With the enhanced pretreatment capabilities in Singapore, we are able to broaden the current raw material pool and explore new ones.”

He adds: “We are also currently developing other solutions alongside this as well, such as Power-to-X solutions, but they are still a bit further down the line.”

The expansion at the Singapore refinery is only the beginning, with Neste’s other refineries in other parts of the world also set to significantly increase the company’s production capacity in the coming years. The positive impacts will be felt by everyone looking to make more sustainable choices and to contribute to the global transformation to a circular bioeconomy, where fossil-based products are no longer king.

Credits: Dr. Eva Amsen, a science writer and communicator whose work has appeared on Forbes, Nautilus and The Scientist.