Transportation

4 minute read

Porsche, Karlsruhe Institute of Technology and Neste studied renewable diesel under real life conditions across 1.6 million kilometers

Closing in on the year 2030, we are also closing in on the first major interim target when it comes to reducing greenhouse gas (GHG) emissions and efforts to limit CO2 concentration in the atmosphere. Transportation must pay its share of the bill to make sure that these targets are met. To test the viability of renewable diesel (also known as “HVO100”, with HVO referring to hydrotreated vegetable oil), Porsche, Karlsruhe Institute of Technology and Neste tested renewable diesel in truck transportation across a total of 1.6 million kilometers.

“Does it really work?” This question has been heard frequently over the last years in discussions in Germany related to the approval of renewable diesel for public sale. It is a legitimate question: While renewable diesel comes with clear benefits with regards to GHG emissions when all the emissions over the fuel’s life cycle are compared to fossil diesel, it also has slightly different chemical characteristics, e.g. when it comes to energy density or cetane number. While it has been used in other countries for several years already, a consortium of three parties – car manufacturer Porsche, renewable diesel producer Neste and researchers at Karlsruhe Institute of Technology – made it their task to provide a definitive and detailed answer. Further project members were Müller – Die lila Logistik, EDi Hohenlohe and TOOL-FUEL.

So in 2020, the parties put on their detective hats to take a closer look at the issue. The following is a summary of a more comprehensive article published in Automotive and Engine Technology in 20241:

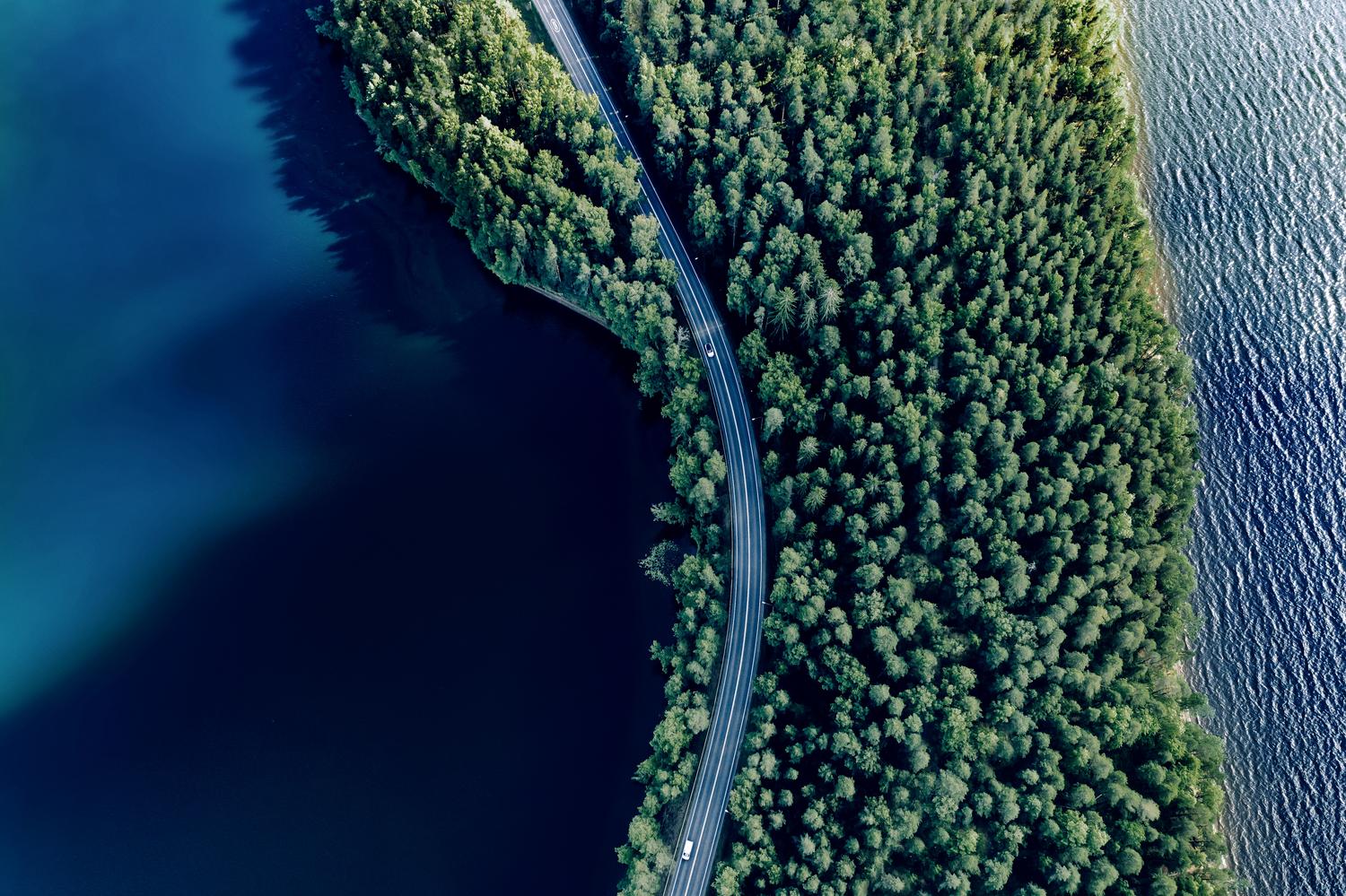

Image: Neste MY Renewable Diesel burns cleaner than fossil diesel. But does that affect its operational efficiency? Time to find out.

The setup: 12 trucks, 3 routes, 1.6 million kilometers

An endurance run featuring up to 12 trucks running on 100% Neste MY Renewable Diesel™ (HVO100) was kicked off, with each truck having a twin truck running on conventional fossil diesel. The goal was to look at real-life conditions with existing traffic and infrastructure use instead of the comforting warmth of a laboratory.

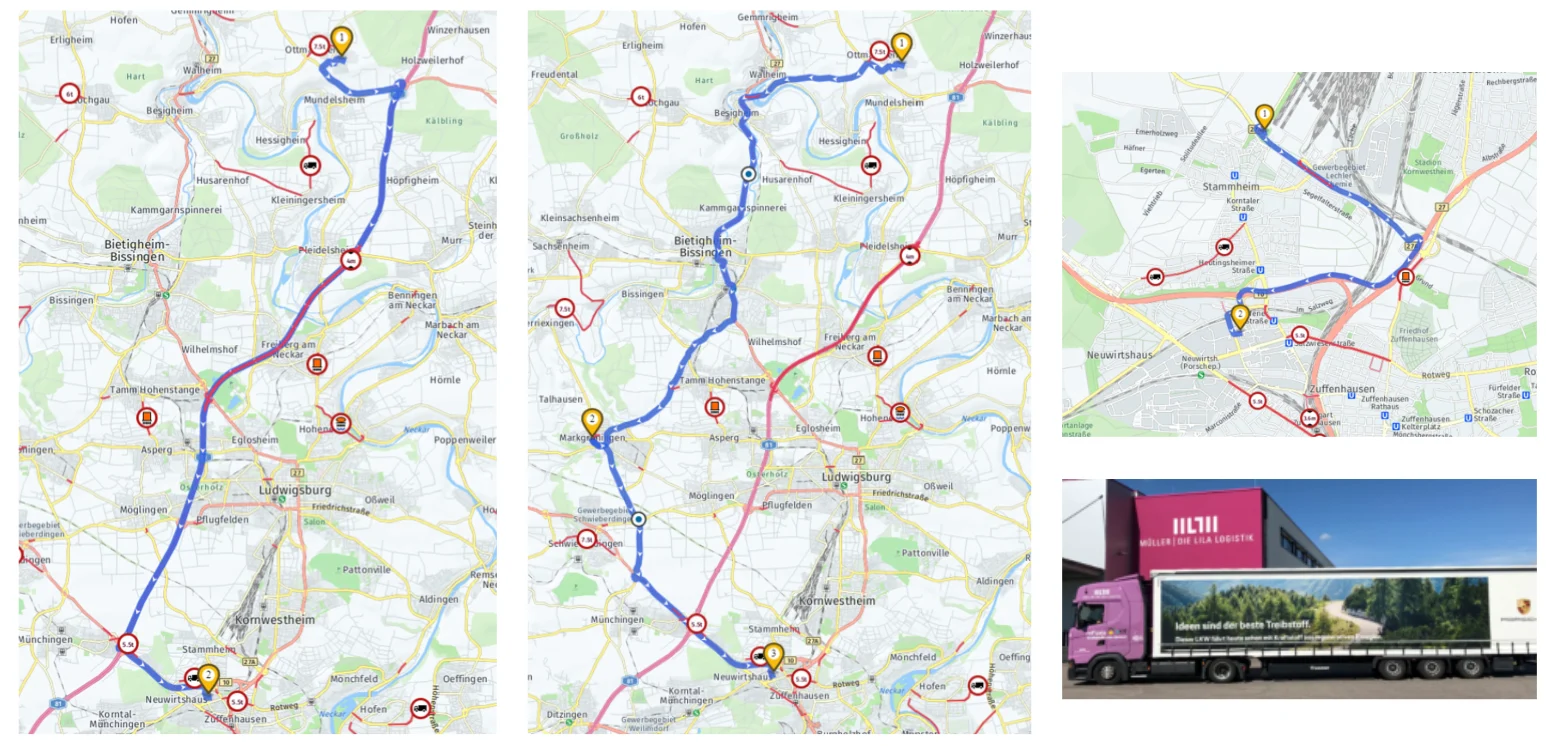

For the mix of new and used Scania and MAN 40t lowliner trucks, three different routes in the supply chains of Porsche’s site in Stuttgart-Zuffenhausen were picked – manufacturing site for Porsche’s sports cars and the electric Porsche Taycan:

A highway route, 70km long with a 60km share of highways.

An overland journey of 85km with no highway sections at all.

A short-haul city route of 10km through urban traffic.

Image: From left to right: Highway route, overland route and short-term haul city route. Truck participating in the endurance run.

To supply the trucks running on renewable diesel, Neste’s distribution partners EDi Hohenlohe and TOOL-FUEL provided a mobile 5,000 liter filling station, which was located at the site of Müller – Die lila Logistik in Ottmarsheim. The twin trucks not running on renewable diesel were fueled with conventional B7 diesel.

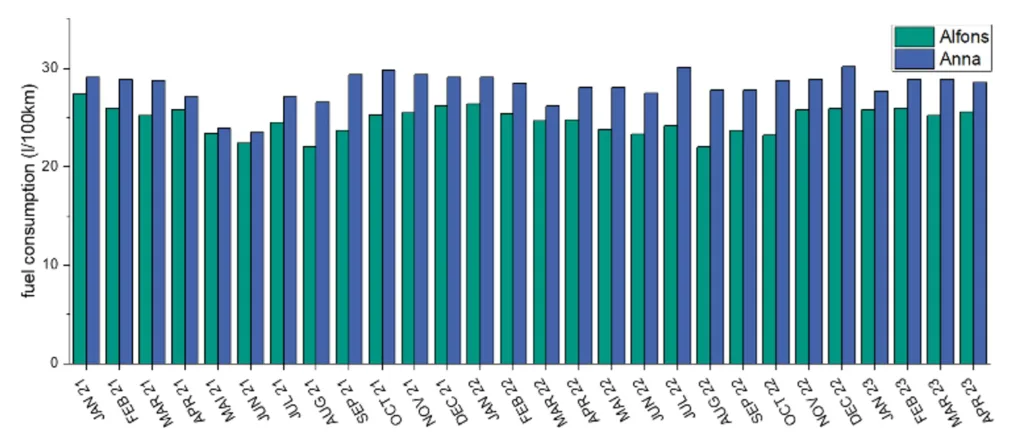

The results: slightly lower consumption for renewable diesel over fossil diesel, operations otherwise unaffected

One expectation was a higher consumption of the trucks running on renewable diesel due to the lower energy density of the fuel. The project team was in for a surprise though: In fact, the trucks running on renewable diesel ended up with a slightly lower fuel consumption than those running on B7 diesel – meaning that the expected additional volumetric consumption of fuel is too small to be measured. The fact that the exact opposite happened – lower consumption for the renewable diesel powered trucks – was attributed to a change in the behavior of the drivers who knew that they were driving on a more sustainable fuel and may thus have driven more consciously.

Graphic: Monthly consumption of a test pair of trucks named “Alfons” and “Anna”, with “Alfons” powered by renewable diesel and “Anna” by B7 diesel.

Analyses also focused on the oil of the trucks as a permanent sensor of changes in combustion. The oil analysis showed no indication of fuel-related differences, most notably:

No abnormal fuel-related oil dilution

No deviations in soot emissions

No increase in nitrogen oxide (NOx) emissions

Sulfur dioxide (SO2) emissions below measurement limit

In summary, the endurance test confirmed that using renewable diesel is a tool for significant greenhouse gas emissions without negative effects on other parameters, which may also be the reason why the largest manufacturers of heavy commercial vehicles, such as Liebherr, Volvo Trucks, John Deere, Caterpillar, Scania, Mercedes Benz, DAF and MAN have already approved renewable diesel in neat form for use.

1) Endurance results of a refuels fleet test in a real application based on directly comparable truck test pairs. Toedter, O.; Weyhing, T.; Koch, T.; Fritzsche, M.; Rodrigues, C.; Dörr, S.; Stöhr, A.; Weissert, R.; Hübeler, J.; Behrens, C. 2024. Automotive and Engine Technology, 9 (1), 1. doi:10.1007/s41104-024-00139-1