Plastics

7 minute read

Plastics: Can they be sustainable?

Our excessive use of plastics takes a toll on the environment. Doing without plastics may sound as the logical way to avoid their negative environmental impact, but it would also strip us of a versatile and widely used material. Are there ways to avoid negatives while keeping the benefits?

Plastics have become part of our daily lives due to many positive aspects, ranging from durability to performance, from versatility to economics. But, across the globe, plastics are still mostly made from fossil resources and most plastic waste isn’t recycled.

A regional example to depict a global issue: In Asia, particularly Southeast Asia, plastics pollution poses a pressing challenge to the countries’ environment where rapid industrialization, urbanization and population growth have exacerbated its impact. With an increasing reliance on single-use plastics coupled with inadequate waste management infrastructure, the region faces a grave environmental crisis.

Plastics pollution poses a pressing challenge to many countries and regions.

At the same time, the need to reduce greenhouse gas (GHG) emissions from fossil resource use becomes more and more visible through extreme weather phenomena. Research by The Circulate Initiative, a non-profit organization, shows that recycling all mismanaged plastic waste in South and Southeast Asia can reduce greenhouse gas emissions by 229 million tons, the equivalent of shutting down 61 coal-fired power plants.

What’s described for Asia doesn’t look very different in the rest of the world and it sums up the dilemma we are in. The urgency to address the climate crisis is rather well-known globally, but there is a similar urgency to tackle the plastics pollution crisis, underscored by its profound impact on biodiversity and particularly marine ecosystems, public health, and socioeconomic well-being.

What can the world do? There are three options to solve this:

Stop using plastics. It’s as simple as that: Not using plastics anymore would reduce the use of fossil resources and stop plastic waste generation. However, we’d also give up on the positive aspects of the material, while we would need to find alternative solutions to replace all the plastic we currently use.

Ignore the negatives. We’ve been living with fossil plastics and the waste for many years, decades even. We could just swallow all the negative side effects and carry on without any changes to our lives or how we conduct our businesses.

Change how we make and use plastics. Fossil resources aren’t the only way to make plastics – and plastic waste not being recycled isn’t a law of nature. We could implement more sustainable ways to make plastics and take good care of the waste.

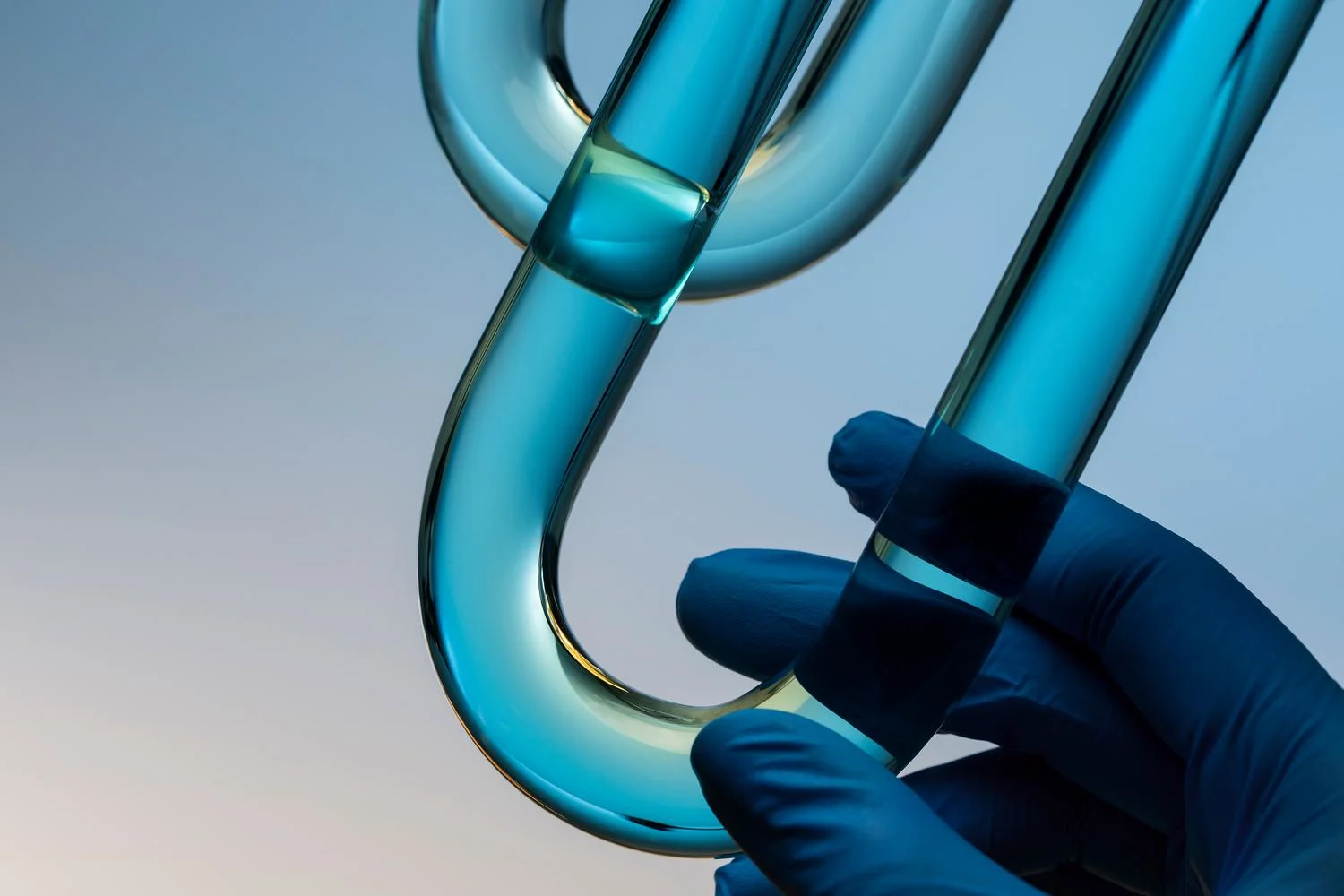

Option 1 would be very difficult to implement. While there might be products that could be produced without plastics, there are also applications of plastics that play a crucial role in our lives – and for some of these it would be difficult to find other materials. Think about healthcare applications where plastics ensure hygienic use, e.g. tubes for fluid supply or surgical instruments. A full stop to plastics therefore isn’t really a realistic solution.

In many sensitive applications, replacing plastics would pose quite a challenge – healthcare is one of these areas.

When it comes to Option 2, we all have seen some of the impacts of climate change. It will ultimately make many parts of our planet hostile to human life. At the same time, plastics littering slowly ruins the habitats of various species already today, including our own. Hence, ignoring the waste problem and continuing to use fossil resources as if those negative impacts didn’t exist isn’t a desirable scenario either.

This leaves us with Option 3: If we want to continue using plastics, we have to become better – in making them and in dealing with their leftovers. It won’t be easy to change an entire industry. Luckily though, the technologies to start are available. It’s not as much a question of “how?” anymore, it’s more a question of “how fast?”.

Solving the fossil resource issue

To phase out fossil resources from plastics, let’s consider what fossil resources actually are for plastics: a source of (hydro)carbon(s). To make plastics without fossil resources, we therefore need to find other sources of carbon. There are three general alternatives we could tap into:

Carbon from the atmosphere: Our atmosphere is rich in carbon in the form of carbon dioxide (CO2). There are technologies that take CO2 from the atmosphere and, adding hydrogen, turn it into hydrocarbons. The good news: there is so much carbon in the atmosphere, we could create a lot of hydrocarbons from it. The bad news: while technically feasible, the processes need to be further optimized and scaled up to become a feasible solution.

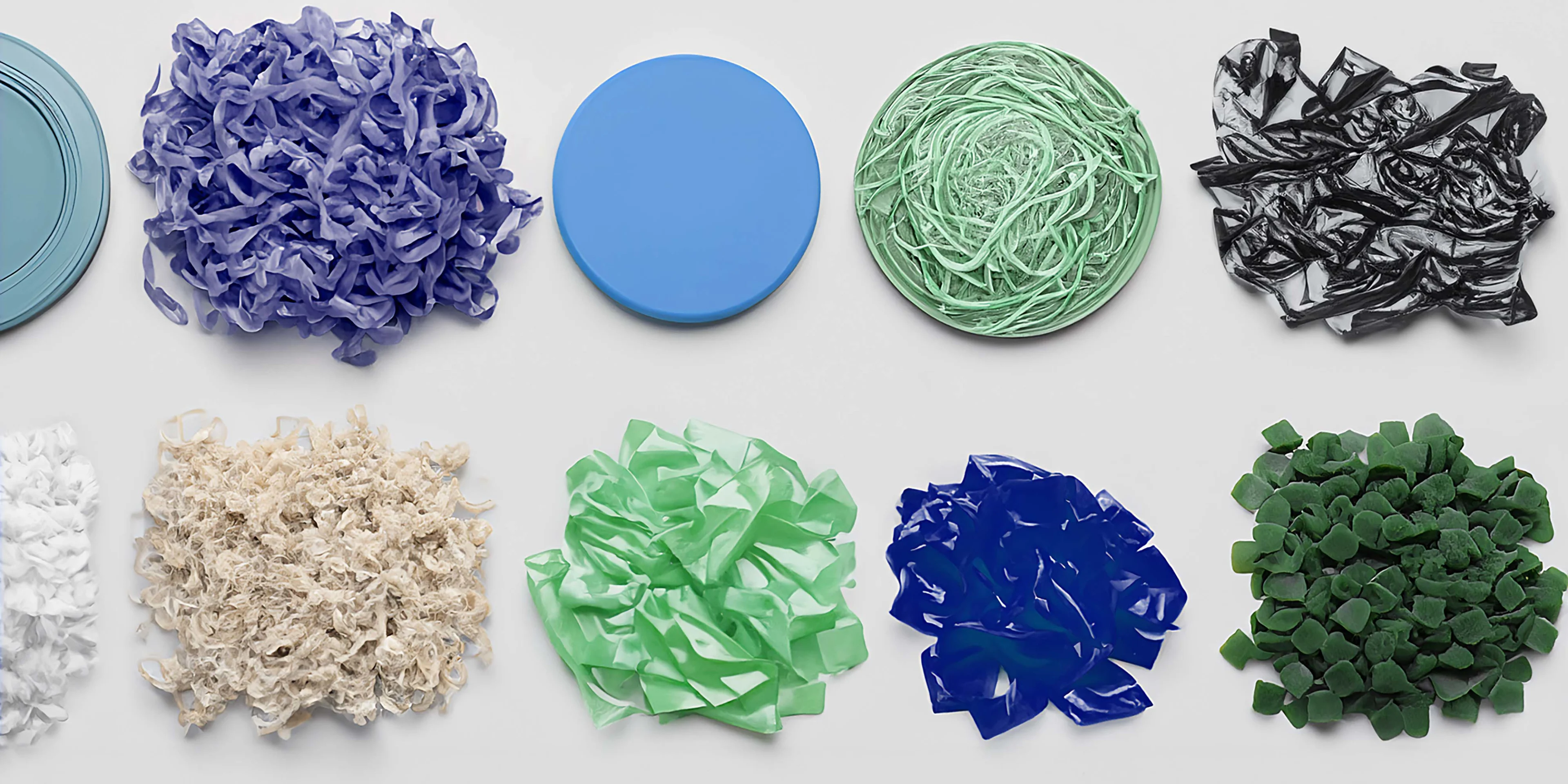

Carbon from the technosphere: There is a lot of carbon in the things we as humans created, for example plastic waste. Through recycling, we can reuse that carbon and use it again. The good news: there are existing as well as emerging technologies to do so. The bad news: we are far away from collecting and recycling enough plastic to have enough carbon to meet the demand for new plastics.

The biosphere offers plenty of carbon that can be used to create all kinds of products, including materials.

Carbon from the biosphere: Every living thing is made of carbon, including the flora of our planet. We can use this renewable (bio-based) carbon to create plastics. Good news: it’s available at scale and it works. We have technologies at our hand that can turn various renewable or “biogenic” materials into hydrocarbons – and they can then be turned into the same plastics that are currently made from fossil resources. These biogenic materials can come in different forms: residues from vegetable oil production or oil and fat waste such as used cooking oil are possible sources. These plastics come without compromises on safety, performance or durability. In fact, one couldn’t tell the difference between plastics made from renewable raw materials and fossil ones. At the same time, it’s a solution available at industrial scale: Neste alone has a production capacity of 5.5 million tons of renewable products, set to increase to 6.8 million tons in 2026. Various products have already been made with the bio-based raw materials of Neste, ranging from diapers to pacifiers, from coffee caps to bento box packaging, from construction materials to medical devices such as catheters. Replacing fossil resources with bio-based materials in plastics value chains therefore offers a significant opportunity to make more sustainable plastics.

Taking care of plastic waste

The second issue that needs to be addressed is plastic waste. To do so, the first step has to be collecting plastic waste more efficiently. One motivator for that is adding value to plastic waste – and this value can be derived from recycling. For that, we need to scale-up the use of existing recycling technologies such as mechanical recycling. Whenever possible, plastic waste should be mechanically recycled into new plastic products of value. At the same time, we need new recycling technologies to recycle plastic waste that is difficult to recycle with current means. Chemical recycling offers a promising, complementary technology here that is currently being turned into a large-scale solution. Together with mechanical recycling and an expansion of plastic waste collection systems, we have the required technologies at our disposal to turn plastic waste into a valuable resource that is too precious to be thrown away.

A sustainable future for plastics

By phasing out fossil resources from plastics manufacturing and increasing the use of renewable and recycled materials, we can gradually reduce the carbon footprint of plastics. By increasing the recycling of plastic waste, we can gradually reduce plastic waste pollution. We, therefore, have all the means we need to transform the plastics industry, allowing us to eliminate the negatives from the plastics equation while keeping the positives and benefits.

There’s still a long way to go but immediate actions are available to tackle the plastics pollution, today. What are we waiting for?