Plastics

6 minute read

How can traceability help verify sustainability in polymers and chemicals?

Did you ever buy a product that claimed to be sustainable and wonder, how that claim can be substantiated? Together with the Netherlands-based startup Circularise, Neste is taking up the challenge of substantiating such claims in the polymers and chemicals industry.

Strolling through a store or supermarket, shoppers are confronted with all kinds of claims. When buying a product, most of them trust the manufacturer that the information and claims associated with the product are correct – and what else can they do? Only very few claims can be easily confirmed. “Tastes like strawberry” might be one of the easier ones to check, simply by eating it. With “less sugar” it already gets trickier: when verifying that, a basic class in food science and a small laboratory come in handy. Yet, it gets even more difficult when it comes to claims that don’t directly affect the product or its properties, but rather relate to the production processes or the conditions the product itself or its raw materials have been subjected to. Sustainability-related claims often fall into this category – and in the face of climate change, they are becoming more and more important.

“Sustainability is currently built as a trust game,” says Isabella Tonaco, Vice President Strategy Execution & Marketing from Renewable Polymers and Chemicals business unit at Neste, who is working on defining sustainability-related claims for companies in the polymers and chemicals industry. “It’s not easy to verify sustainability in many cases. It’s not just about the product itself, but about how that product has been processed – and we might not be able to tell any difference in the physical product.”

One key to back such claims is being able to track and trace the materials used for the products. For the business with renewable fuels such as renewable diesel or Sustainable Aviation Fuel i.e. “SAF”, Neste has a long history of putting emphasis on raw materials traceability. In fact, all the renewable raw materials Neste uses are traceable back to the point of origin as the law requires of biofuels producers; either to the cultivation sites or production plants concerned. This allows the company to make verifiable claims about products such as Neste MY Renewable DieselTM or Neste MY Sustainable Aviation FuelTM. The same is true for Neste’s renewable polymers and chemicals business, but there is a big difference to the fuels business. In the polymers and chemicals industry, Neste and the company’s products are just the starting point of very complex downstream value chains.

Supply chain complexity makes it difficult to keep track of materials as a lot of different intermediate and production steps are included. In addition to that, there might be no difference in quality or performance between more sustainable plastics solutions and conventional ones. That’s because on a chemical or molecular level, the materials may be similar and the sustainable character of the materials used may not be measured by analyzing the final product. Claims such as “lower carbon footprint” or “recycled materials” thereby become very difficult to verify.

Furthermore, a lot of more sustainable solutions in this industry are being introduced via mass balancing. Mass balancing means that the manufacturer is using a certain percentage of sustainable materials to replace conventional, virgin fossil based materials, and these sustainable materials are then being allocated to products for different customers. Despite the verifiable volumes of sustainable materials used in the production, the amount of it actually ending up in each of the products may vary. It’s similar to green electricity: you can ask your electricity supplier to provide you with green electricity and they will make sure to produce the amount of electricity you use from renewable sources. However, in the public grid, electricity from all kinds of sources gets mixed up. Hence, not all of the electrons powering your fridge may come from renewable sources but you will just know that for every kilowatt-hour consumed to power your home, there is a kilowatt-hour being produced from renewable sources to replace electricity use e.g. from fossil sources.

Due to mass balancing, a product may be linked to 100% renewable raw materials but physically contain less than that. Hence, trust and traceability become key. At the same time, mass balancing has its benefits for the climate.

“The advantage of mass balancing is that it enables the industry to have an immediate impact in combating climate change. More sustainable solutions can be introduced incrementally,” explains Isabella Tonaco. “Mass balancing thereby helps accelerate the reduction of greenhouse gas emissions."

Complex value chains using mass balancing create an urgent need for solutions to track and trace materials throughout the chain. This provides benefits to all partners in the value chain as they can be certain about the characteristics, e.g. sustainability, of the materials they are sourcing or the product they are buying.

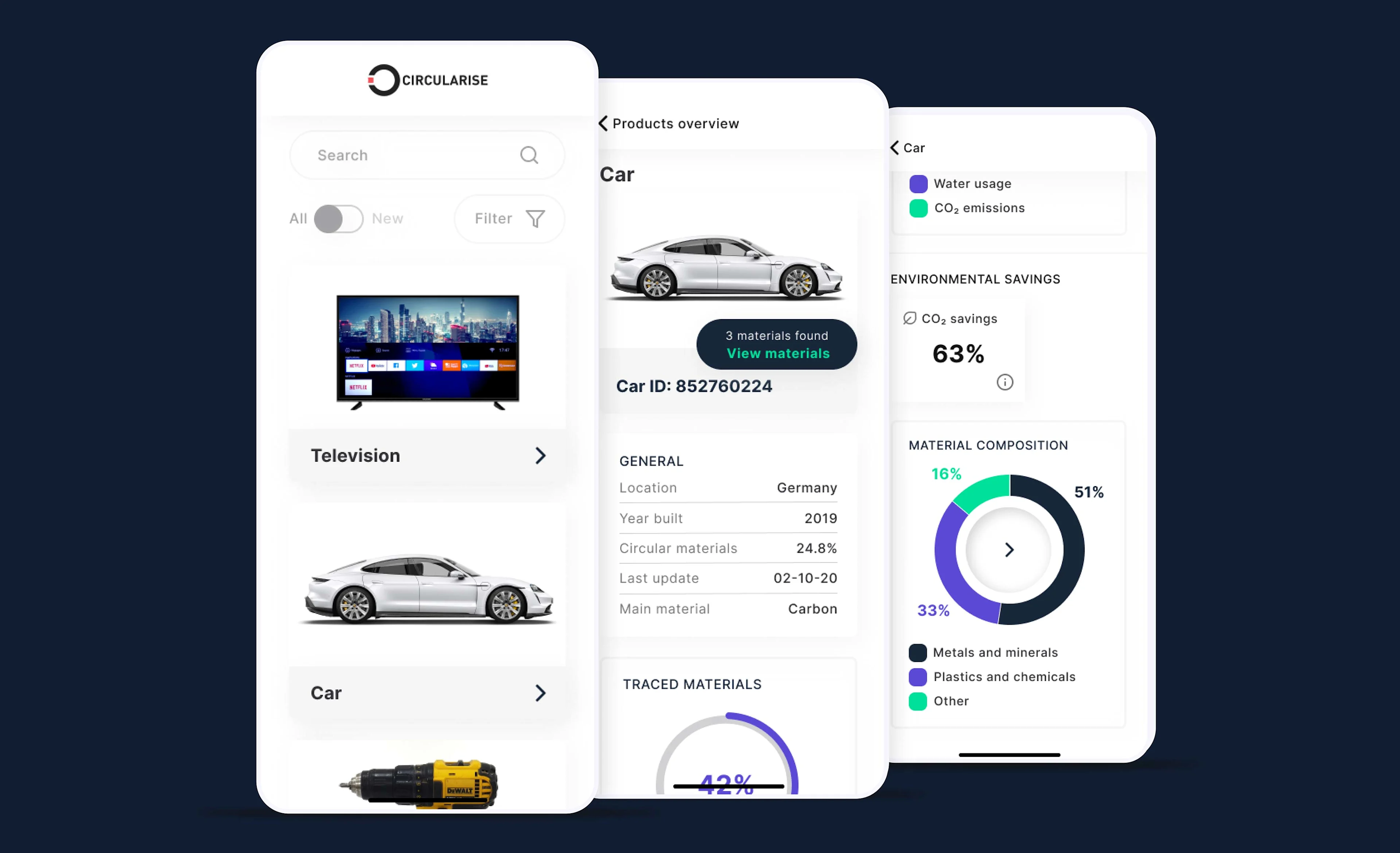

Neste and Circularise have joined forces to tackle this issue. Neste intends to use Circularise’s traceability software to increase the transparency of material flows in the polymers and chemicals value chains. The idea is simple: right from the start of the value chain, a digital twin of the raw material used in the production is created. These digital twins can be considered a digital product passport for the material that is being transferred along the value chain.

Digital product passports store all different kinds of information on the materials, ranging from their point of origin to their carbon footprint. When the materials are processed, additional information is then added to the digital twins, for example, where and how the materials were processed. Information in the digital product passport is selectively shared with members of the value chain, providing valuable information about the materials and products in the supply chain. This information becomes especially valuable the further downstream in the value chain we get: with the help of the digital twins, brand owners are able to make verifiable claims about the materials that have been used for their products with confidence. All materials can be traced back upstream easily with this traceability software despite the complex supply chain.

“The Circularise software supports mass balance by design, making the digital product passports we create ideal for tackling the traceability challenges of complex supply chains,” Mesbah Sabur, co-founder of Circularise, explains.

“Circularise’s software is a public blockchain-based solution,” says Mesbah. “This makes it impossible to manipulate the data, strengthening trust in the information being shared. Smart Questioning technology then allows the selective sharing of key insights between parties, without risking any sensitive data.”

So the next time a consumer buys a polymer or chemicals-based product featuring claims about sustainability, the manufacturer or consumer will be able to verify what raw materials were sourced, how they were processed, and the entire environmental impact of the end product.