Plastics

10 minute read

The plastic waste brothers: how mechanical and chemical recycling are two sides of the same coin

The issue of plastic waste won’t go away on its own. Stagnating recycling rates make it clear that more of the same won’t get us far. New solutions are desperately needed unless we want to drown in mismanaged waste. To make today’s recycling limitations and possibilities visible, let’s follow the life of two unlikely siblings: Bob and Barney, the plastic brothers.

We produce plastic waste. A lot. In 2019, some 353 million tons of it was generated worldwide. And our thirst for plastic isn’t satisfied yet. It is estimated that by 2060, the figure will increase to a billion tons. Every. Single. Year.

The good news is: plastic can be recycled. At least in theory. The bad news is that we don’t do it sufficiently. Just 10% of global plastic waste is eventually being recycled. 90% are not. Why only 10%? A simple question with a not so simple answer.

Let’s give it a try by following the life of two similar, yet different siblings: Bob the bottle and Barney the bag. Bob is a shampoo bottle, made of high-density polyethylene, a very common type of plastic. His brother Barney is a little mozzarella cheese bag, made of multiple layers of polyethylene and polyamide, commonly found in food packaging.

Bob and Barney lived a fulfilling life: in your bathroom, preserving the fragrance of your favorite shampoo. In your fridge, keeping that cheese fresh and bestowing you a high protein meal. Now that the last drop of shampoo has been used and all the mozzarella is in your tummy, Bob’s and Barney’s adventure has finally come to an end. What remains is their final passage over to the eternal hunting grounds of plastic packaging. Here is their story.

You can’t recycle what isn’t collected

To recycle plastic waste, one needs to collect it. Bob and Barney aren’t that cumbersome, so how hard can it be, right? Wrong. While the infrastructure for collection is established in certain regions – in Europe, for example – this isn’t the case globally. Only some 14 percent of plastic waste is actually collected for recycling. The majority goes into landfills, incineration or is mismanaged. While Bob and Barney might love to swim in the ocean or rest in a forest, this is not the place for such merited individuals to spend their eventide… aside from being an environmental nightmare.

Collection is only half the story, though. Catching Bob and Barney might be one thing, recycling them is another. It requires infrastructure and facilities. Guess what: they are nonexistent and not even developed in many parts of the world. Hence, about half of the plastic waste collected for recycling may still end up in landfills or incineration.

As of today, only a small amount of plastic waste is recycled globally.

Not all plastic waste is the same

What adds to the challenge: plastic waste is a wide term. While Bob and Barney are undoubtedly plastic items, they have different properties and characteristics. Bob is a ripped, firm bottle, while Barney is… well, a bag (nothing personal, Barney). Different in shape and size, they also come in different colors. While Bob is monochrome, Barney has been printed on with shiny colors advertising cheese qualities. Finally, Barney is made of multiple materials, while Bob is made of just one.

All these differences lead to some plastic waste being rather easy to recycle, while other waste is not. For example, a PET bottle, such as those storing our soft drinks, is a piece of plastic that can be quite easy to recycle. A rule of thumb is this: the purer and cleaner plastic waste, the easier to recycle.

Life is a roller coaster – also for plastic waste

But let’s see how Bob and Barney fare. Let’s assume that the model citizen you are, you have separated your waste and discarded both in a container for plastic waste.

Together with other plastic items, they are transported to a sorting facility - and in for a roller coaster ride: traveling across conveyor belts, different types of waste are being separated. The sorting plant uses various processes for that: plastic foils are removed using a vacuum, a screen drum separates smaller and larger pieces, a wind canal separates based on weight. Magnets remove screws or other metals that ended up in the wrong place. Finally, scanners identify items to single out individual pieces. Eventually, our brothers bid their farewell and are separated.

Is it you, Bob?

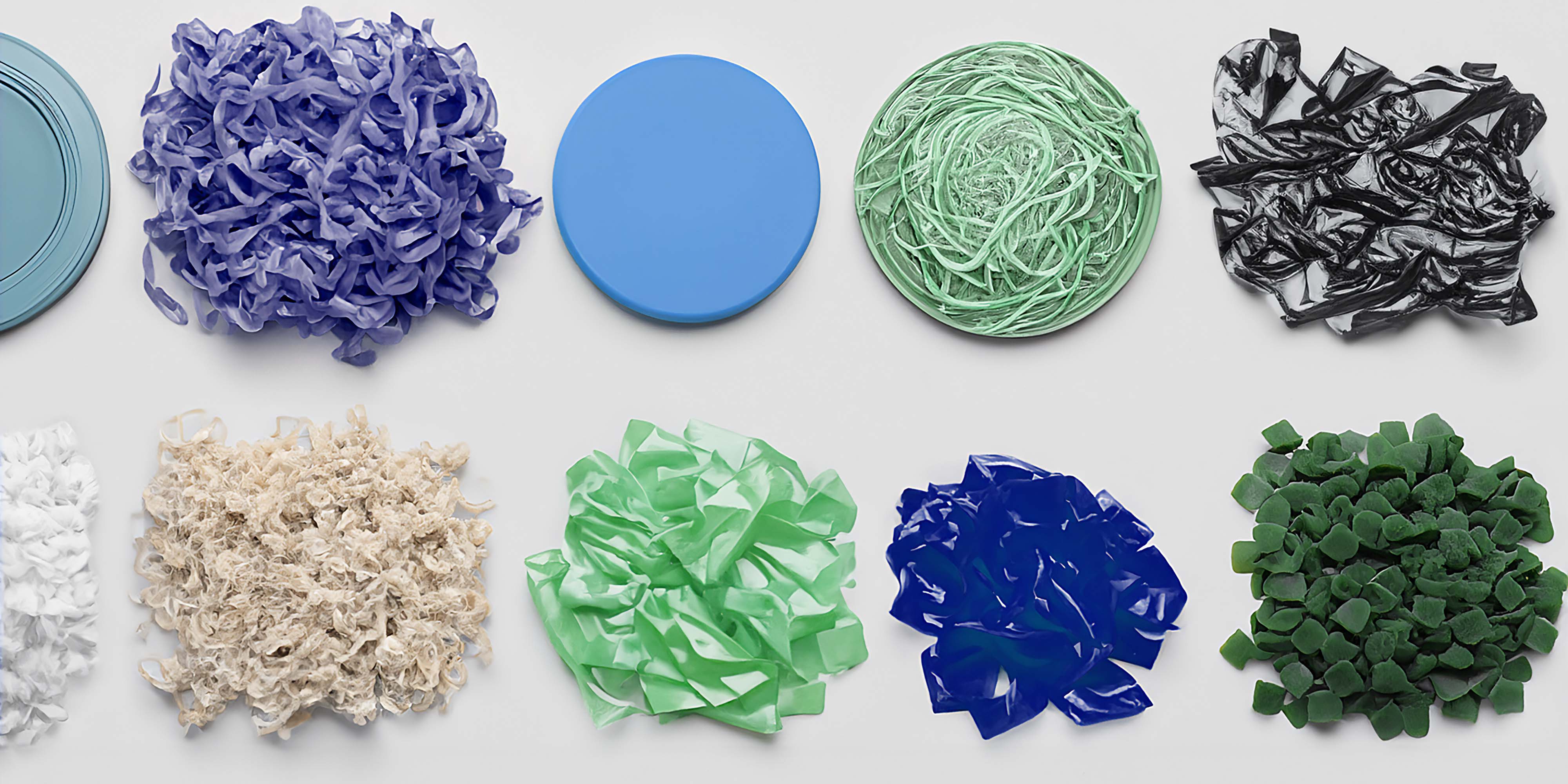

Bob the shampoo bottle ends up with other similarly colored bottles and items. They are baled – compressed to reduce volume – and transported to a mechanical recycling plant. There, the waste might be sorted once more before being shredded into little pieces. After taking a proper shower and some thorough drying, they enter an extruder. The extruder uses temperature and pressure to melt them down and create plastic recyclate pellets. These can be formed into new plastic products.

Can you spot Bob? Shredded waste plastic.

While Bob’s shower allows to remove some unwanted substances, the recyclate may still contain impurities. This is why mechanically recycled material is pushing its limits when it comes to high standards for purity of products; such purity is essential e.g. in food-contact packaging and medical applications. You might not want to use Bob or what’s left of him to wrap your sandwich or store a blood donation. However, there are applications that Bob can be a part of: park benches are a common example or plastic pipes and buckets.

Mechanical recycling is a great method to make sure applications with lower material requirements do not need to be made from new, virgin plastics. So, the next time you take a rest on a park bench, it might be Bob enjoying his second life and keeping your back straight. Lucky you, Bob!

Everyone likes the cheese, no one likes the bag

Now where did Barney go? Right, we are back at the sorting plant. Barney the bag wasn’t as fortunate as Bob. Barney isn’t material that can be mechanically recycled. The colorful imprints and the multiple materials make Barney unpopular in that regard.

Any attempt to recycle Barney via mechanical means would result in an indistinguishable mixture of different polymers. The result: poor quality. Barney is what we typically call “hard-to-recycle”. He will therefore be treated like regular waste. He may find himself in landfill or incineration. In landfill, Barney will slowly decompose, releasing his carbon content into the atmosphere in the form of CO2. In incineration, this process is accelerated: the CO2 will be emitted quickly, adding to the amount of CO2 in the atmosphere, yet serving the purpose of generating energy. In both cases, there is no second life for the bag. Poor you, Barney!

Hope for Barney!

To change that, it’s necessary to go beyond the existing recycling processes. This is where chemical recycling comes into play. In fact, Barney is a prime candidate for this technology, which goes one step further than mechanical recycling: it disassembles the plastic into its building blocks, and these can then be reassembled to achieve material similar to plastic fresh from the oven. Consider “oven” an odd choice of words? Not at all!

To visualize chemical recycling, let’s think of old bread. When bread gets stale and rigid, there are great recipes that put it to good use: one is cutting it into small pieces and gratinating it with melted cheese. Congratulations, you just mechanically recycled bread. Chemical recycling on the other hand turns the bread into flour, yeast and water - and whatever other shenanigans the baker put in it. We can then use these to bake a new bread.

Does this mean that Barney can be a mozzarella bag again? In fact, chemical recycling can help Barney become almost anything as we can remove or add ingredients. We can turn the bread into a cake. Or in Barney’s world, Barney could become a plastic bag, a bottle or a sushi box. The latter is especially noteworthy: As chemical recycling allows for the removal of impurities and creates virgin-quality material, it also enables the manufacturing of products for sensitive applications such as food-contact packaging.

Back to Barney’s roots

So how does it work? There are several approaches to chemical recycling. To look at what would have happened to Barney in chemical recycling, we are taking a look at the approach Neste is following. For that, we go back to the sorting plant where Barney ended up in the container with the other hard-to-recycle plastic waste. Instead of going to landfill or incineration, they are now transported to a liquefaction facility. One of the options to liquefy plastic waste is pyrolysis. It uses high temperature and the absence of oxygen to break down the plastic into its constituents.

Neste’s refinery in Porvoo (Finland): Here, the company is looking to process liquefied waste plastic into high-quality feedstock for polymers.

The liquefied Barney – who now resembles crude oil, the most commonly used raw material for plastics – is transported to Neste’s refinery in Porvoo. As the liquefied waste plastic still contains impurities such as nitrogen from his polyamide past, several processing steps take place here: pretreatment, upgrading and refining. During pretreatment and upgrading, unwanted chemical compositions and impurities are removed. At this stage, anything that isn’t carbon or hydrogen can be considered an impurity. In the refining step, the material is processed into high-quality feedstock for new plastics – just like fossil crude oil.

Barney has almost done it now. He is pure hydrocarbons on their way to freedom. His next journey takes him into a steam cracker to be turned into e.g. propylene or ethylene, before being polymerized into polypropylene or polyethylene. Barney’s second life has begun and the plastic circle has been closed. Just like his brother Bob, Barney is being put to good use again – and could be re-used again and again and again.

The promise of a circular economy

The story of Bob and Barney shows us why a circular economy requires both technologies: mechanical and chemical recycling. Without mechanical recycling, we would miss out on the opportunity to recycle materials that are as easily recyclable as Bob and his kin. To offer a perspective for materials like multilayer and colorful Barney, we need chemical recycling.

They are pieces of the same puzzle, and without one, the puzzle is incomplete. Further, a circular economy requires proper waste management and collection as well as sustainable product design: By designing products with recycling in mind, we can ensure that materials are easier to recycle, and reduce the waste that ends up in landfills or incinerators.

Does this mean Barney the bag is just bad design at work? Why not use just one single material. The answer is that especially in food packaging, different materials may be used for good reasons. Yet, with the option of chemical recycling, we can make sure food is stored safely and the packaging can still be recycled.

The combined efforts of mechanical and chemical recycling will make a circular economy for plastics possible. In fact, chemical recycling can also help upgrade items made from recyclates. So the next time you are on this website, you might see the story of Paul the Park bench that wants to be a shampoo bottle again. Chemical recycling can make that dream come true for Paul as well. Keep believing in yourself, Paul. You can do it.