Chemical recycling: reduced GHG emissions and fossil resource depletion

Neste completed a life cycle assessment (LCA) (1) on the environmental impacts of chemical recycling as incorporated into the plastics value chain. The study simulates Neste’s approach to chemical recycling, which combines waste plastic liquefaction (e.g. through pyrolysis) with refinery upgrading to produce drop-in feedstock for the production of new polymers, for example plastics.

The LCA concludes that greenhouse gas (GHG) emissions as well as virgin fossil resource use can be significantly reduced if chemical recycling is incorporated into plastics value chains to avoid incineration of plastic waste and replace fossil feedstock use with recycled feedstock in the production of polymers.

LCA with multiple perspectives

The study took on multiple approaches, including a scenario for chemical recycling as a crucial part of a circular economy for polymers, which introduces a new view to the discussion on the technology. The study provides insights into the environmental benefits that can be associated with chemical recycling and provides concrete and measurable data to quantify the technology’s positive impact. Neste’s LCA study features three approaches:

a waste management perspective that considers chemical recycling an alternative to the incineration of waste plastic,

a production perspective that considers chemical recycling an alternative for the production of virgin-fossil feedstock for new polymers, and

a perspective looking at chemical recycling within a circular plastics economy

The LCA covers two time horizons: the near-term (2023) as well as the longer term (2030). These horizons take into account background factors such as electricity mix or increasing capacities for chemical recycling. Regardless of the approach and time horizon, the LCA results show significantly reduced GHG emissions and a reduction in fossil resource depletion (i.e. in the use of fossil resources) in comparison with the situation in which chemical recycling was not used as a solution. For approaches #1 and #2, the waste plastic assumed as input in the value chain is post-consumer waste which is hard to recycle mechanically and would usually end up in incineration (e.g. foil and mixed plastic waste). Approach #3 looks at the whole life cycle of polypropylene and low-density polyethylene and considers these as input instead of foil and mixed plastics. In addition to these three approaches, the LCA study also evaluated the carbon and fossil resource handprints of chemical recycling.

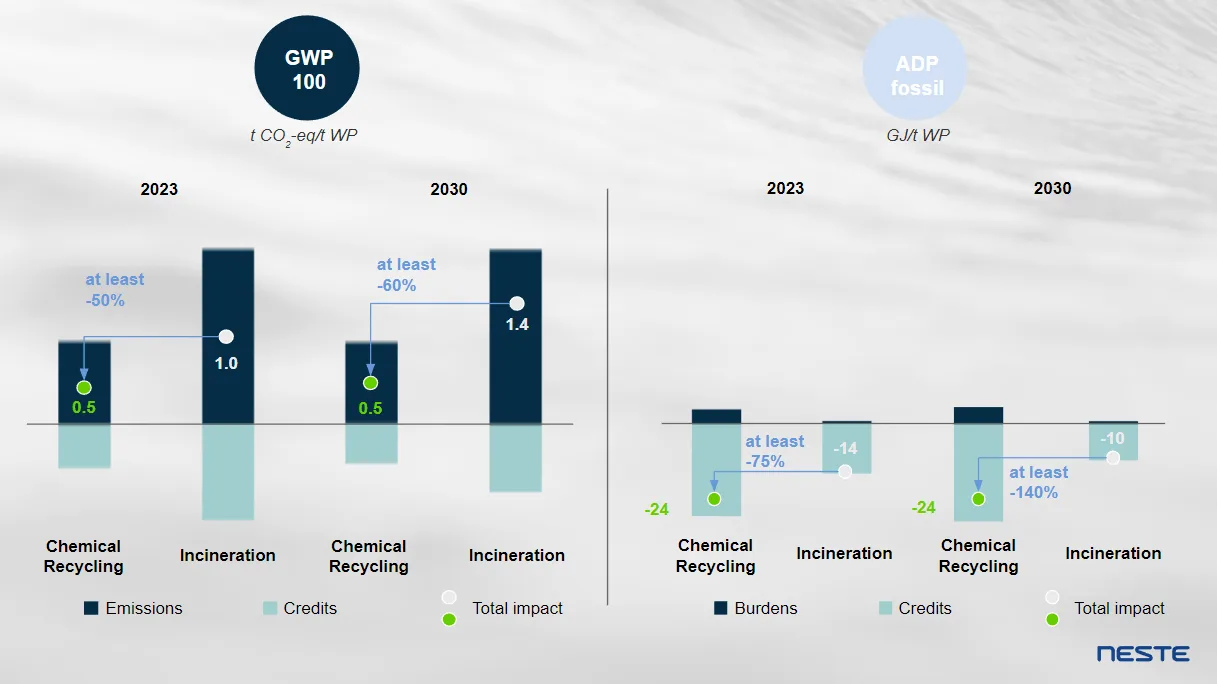

The waste treatment perspective

In the first approach, the study views chemical recycling as an alternative to incineration of waste plastic for energy recovery, currently the most common end-of-life treatment in Europe2. The chemical recycling process steps taken into account include pre-processing (further removal of unsuitable materials, such as paper, PVC and moisture, from a reject stream of mechanical recycling), liquefaction as well as upgrading and refining of waste plastic into a drop-in petrochemical feed. In this case, chemical recycling provides a reduction in GHG emissions of at least 50% (2023) and 60% (2030). The study also demonstrates that fossil resource depletion, i.e. fossil resource use, is reduced by at least 75% and 140%3 respectively when waste plastic is chemically recycled instead of incinerated.

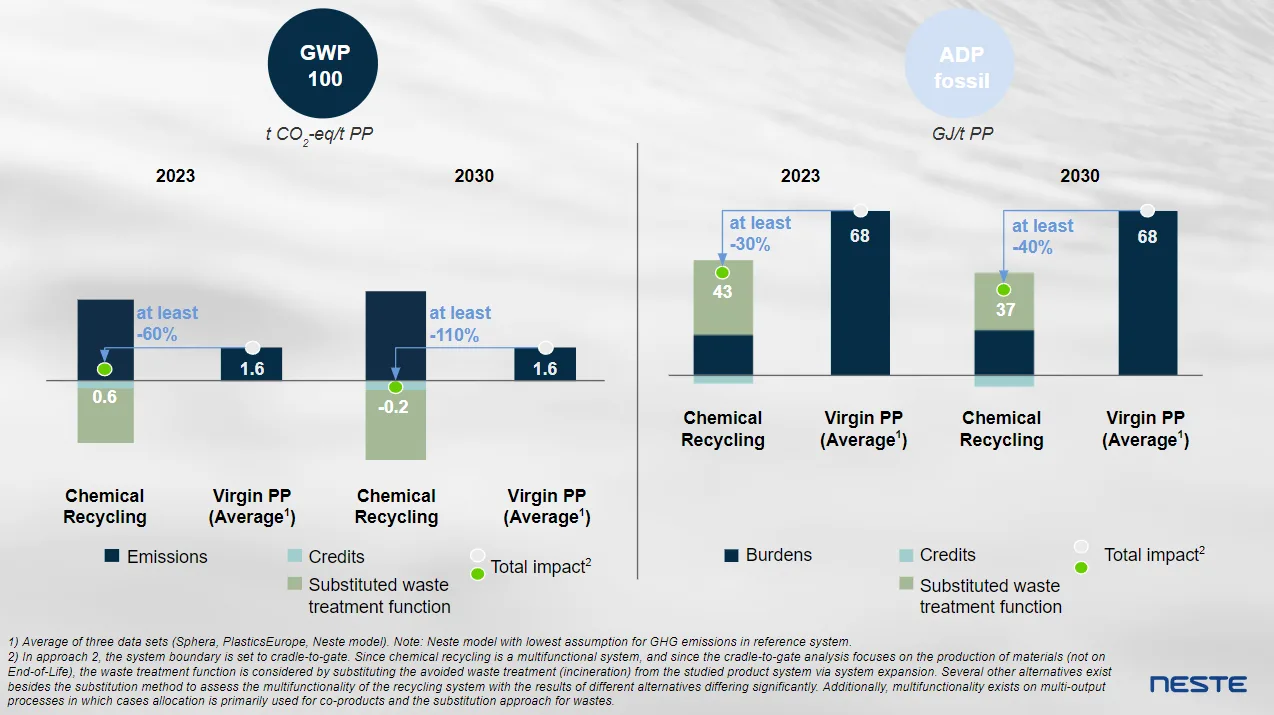

The plastics production perspective

When considering chemical recycling as a means to produce raw material for the manufacturing of new polymers, the study takes into account the following processing steps in addition to the ones in Approach #1: the collection and sorting of waste plastic as well as using the waste plastic derived petrochemical feedstock in a steam cracker and consecutive polymerization into polypropylene.

When compared to the production of virgin fossil naphtha and consecutive steam cracking and polymerization into polypropylene, chemical recycling provides a reduction of at least 60% (2023) and 110% (2030)3 in GHG emissions. The analysis also concludes that fossil resource depletion is reduced by at least 30% and 40% respectively when polypropylene is produced from chemically recycled waste plastic instead of virgin fossil naphtha.

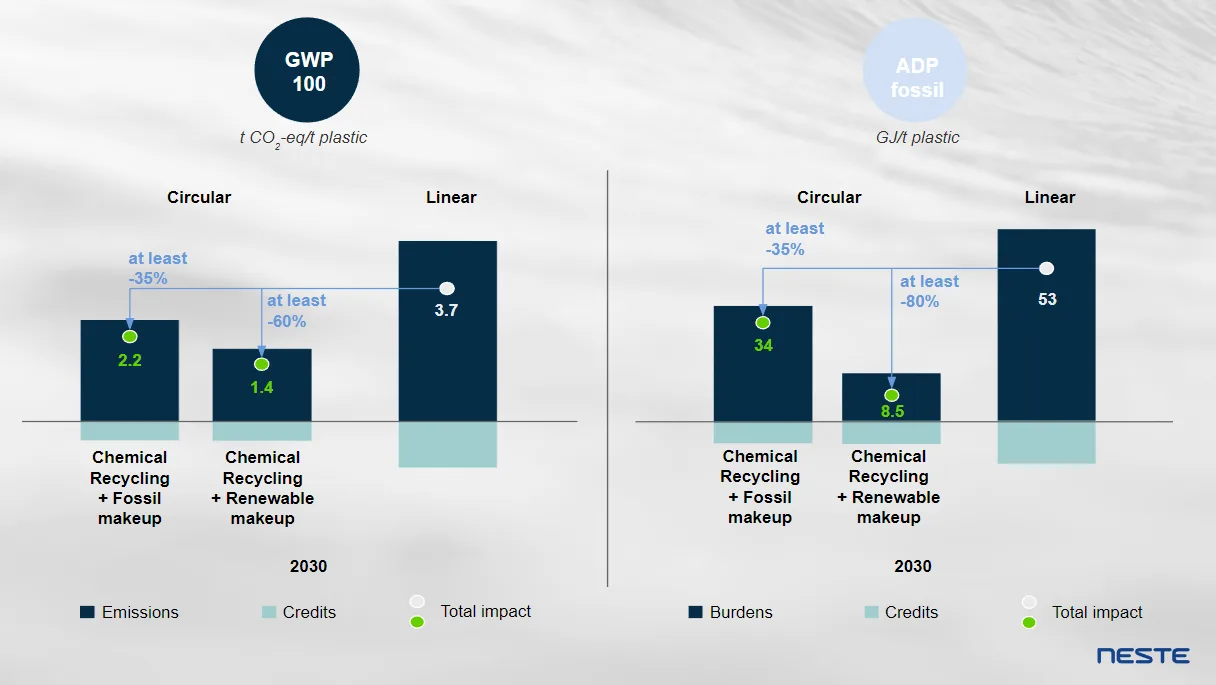

The circularity perspective

Finally, the study considers chemical recycling in a fully circular plastics value chain: the chemical recycling of waste plastic, the production of polymers from recycled feedstock and the management of the waste plastic to start the value chain anew. This is compared to today’s linear value chain starting with the production of feedstock, such as naphtha, from fossil sources and ending with the incineration of plastic waste.

Given that the fully circular economy of plastics is a future model, this approach only looks at the 2030 scenario. Here, chemical recycling provides a reduction in GHG emissions of at least 35% while fossil resource depletion is reduced by at least 35%.

This perspective includes the assumption that not all plastic is produced from chemically recycled feedstock. Due to various sorting and processing losses, around 55% of the polymers are assumed to be produced from chemically recycled raw material, while the remainder is produced from virgin feedstock based on fossil resources.

To account for another trend in polymers production – the increasing use of renewable raw materials – the study also looks at a scenario where this feedstock is based on renewable waste and residue sources. In this case, GHG emissions are reduced by at least 60% and fossil resource depletion by at least 80%.

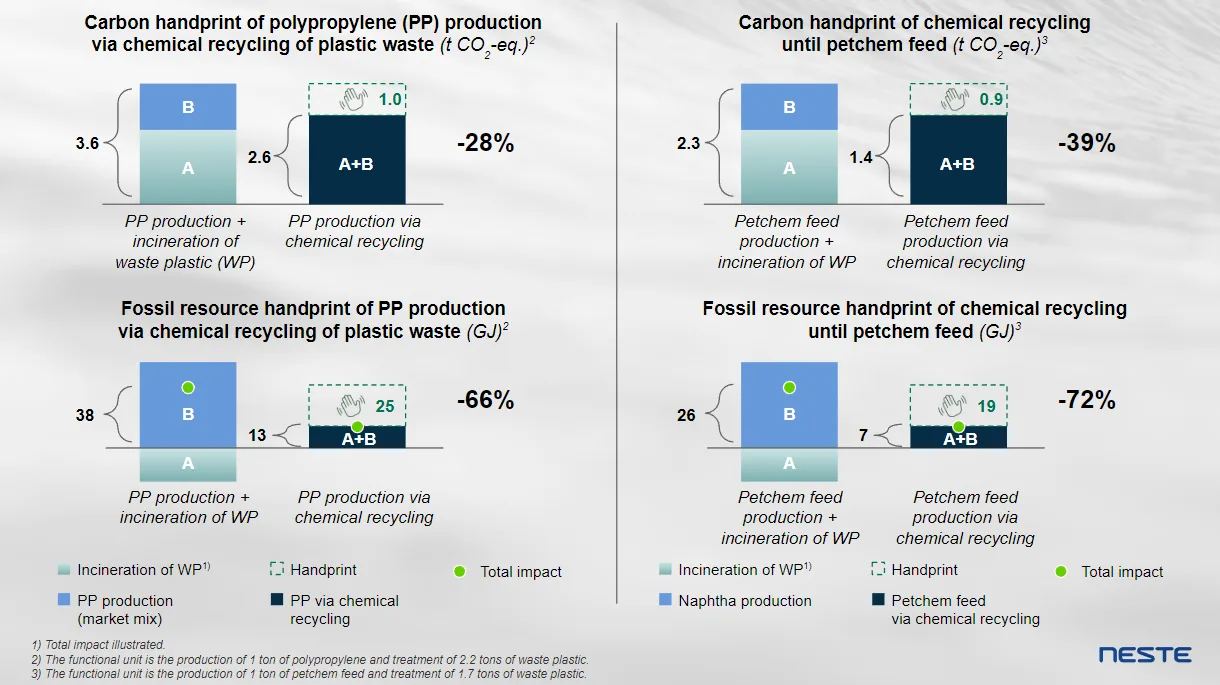

Carbon and fossil resource handprint of chemical recycling

The carbon handprint in the LCA illustrates the climate benefit that can be achieved with chemical recycling compared to the common current scenario in which polypropylene or petrochemical feedstock is produced from virgin fossil raw materials and plastic waste is incinerated. The calculation was done for the 2023 scenario for producing virgin fossil petrochemical feedstock and polypropylene, as well as for the treatment of waste plastic. The carbon handprint is calculated by deducting the carbon and fossil resource footprint of chemical recycling from the footprint of the reference system. It thereby covers the production of petrochemical feedstock and polypropylene, as well as the incineration of the plastic waste.

The carbon handprint of polypropylene produced from chemically recycled waste plastic is around 1 ton of CO2eq. per produced ton of polypropylene – equalling a 28% reduction in carbon footprint over the current scenario. Fossil resource use could be reduced by 66% or 25 GJ per ton respectively. The carbon handprint of petrochemical feedstock produced from chemically recycled waste plastic is around 0.9 tons of CO2eq. per produced ton of feedstock - equalling a 39% reduction in carbon footprint over the current scenario. Fossil resource use could be reduced by 72% or 19 GJ per ton respectively.

Chemical recycling can play a major role in the transformation of the polymers industry

The results of the LCA study show that although the recycling of waste plastic requires several processing steps, the technology provides an opportunity for significant reduction of GHG emissions and fossil resource use in plastics value chains and is well-suited to play its role as a complementary solution to conventional mechanical recycling of plastic. While chemical recycling is available already today at a smaller scale, the results for the 2030 scenarios also show that the reduction in GHG emissions and fossil resource use through the technology can be further increased going forward. Neste believes that the different approaches represented in the LCA study validate that chemical recycling can truly create multiple positive impacts compared to the status quo. Neste would also like this study and its results to provide a basis for a fruitful dialogue also with those who currently have a critical view on chemical recycling.

1) Life Cycle Assessment on Environmental Impacts of Chemical recycling of waste plastic - Case Neste (October 2022).

2) PlasticsEurope: Plastics - the Facts 2022 (October 2022).

3) In case of the reductions beyond 100%, the values for GHG emissions or fossil resource depletion are not only lower than their comparative value but also negative.

Deel dit